Discover more from Customer Obsessed Engineering

Context switching is killing your gains (part 2)

How do we defend our team from distractions? Ad hoc meetings, poorly organized ceremonies, rework, and a host of other demands? A "waste walk" is the answer.

Defend your team

There are a lot of distractions out there, sapping our productivity, keeping us from gettings things done. In part 1 of this article, I talked about how much context switching can hurt our productivity and how to recapture that lost time on a personal level.

So how do we defend our team from an influx of distractions? Ad hoc meetings, poorly organized team ceremonies, rework, and a host of other demands?

Something I love about agile is how successful teams benefit from its relentless focus on productivity. The other side of that coin is that when it’s not working, there isn’t a lot of structure to get things back on track. Agile ceremonies are supposed to keep us focused, but which ceremonies?

If you’re new, welcome to Customer Obsessed Engineering! Every week I publish a new article, direct to your mailbox if you’re a subscriber. As a free subscriber you can read about half of every article, plus all of my free articles.

Anytime you'd like to read more, you can upgrade to a paid subscription.

Awareness is key

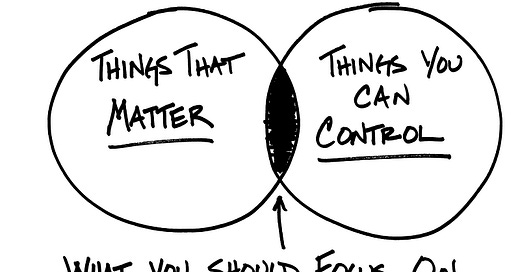

We need an understanding of value add and non-value add work. By value add and non-value add I mean productive effort versus that which isn’t truly efficient or useful to the outcome of your project.

In other words, in order to fix the problem we need to understand how bad it is. Only then we can focus on solutions and make continuous improvements over time.

Agile ceremonies like standups and prioritized backlogs are supposed to defend value add effort — but sometimes it goes off the rails. When that happens there are tools to get us back on-track.

One of my favorite is a waste walk. It’s a structured observation of activity that identifies all the effort that doesn’t add significant value. By identifying waste and brainstorming how to eliminate it, a waste walk uncovers continuous improvement opportunities and leads to efficiency.

A waste walk is wonderful at exposing waste. What’s more, it’s a simple activity. It wraps around your regular sprint or iteration cycle and uses very little effort.

Stop the bleeding

The whole point of a waste walk is to identify where you’re bleeding time, effort, and energy. Discover those activities that suck the team into unproductive work. Activities that consume a huge amount of time but return little or nothing of value. Those are the activities that “hurt the soul” of your team, draining motivation and causing stress or conflict.

But before we can fix the problem we need to recognize there is a problem. The longer we’re exposed to a situation the more likely it gets overlooked. We become numb to the pain because “that’s the way it works.”

We need to make the problem visible again. A waste walk does just that. It creates shared understanding between leaders and teams about current challenges. It exposes “boots on the ground” intelligence about what’s actually happening, versus what was planned.

Part of the key is believing that “the way it works” can always be improved.

A waste walk sheds empirical light on which project methods are working — and which ones need attention. It does this with a few simple actions:

Over a short period, like a sprint, each team member “buckets” their time during the day (this takes less than 5 minutes out of each team member’s day).

At the end of the period, each bucket is aggregated (using a report) into value add and non-value add time (for instance, coding versus unexpected meetings).

The largest aggregate of non-value add effort becomes the team’s focus for improvement.

The following drawing shows the buckets I used during a recent waste walk:

I’ve seen teams realize 40% of their time could be recaptured with more advanced automation, better tooling and improved design effort. After implementing automation and design changes one team gained 37% of their lost time and effort.

That means they went from an average velocity of 15 to nearly 21. It was like the team suddenly discovered 118 hours per week that they put back into the project!

The storied history of waste walks

The waste walk has its roots in Lean Manufacturing. It was originally developed by Taiichi Ohno, the Chief Engineer at Toyota, as part of the Toyota Production System (TPS). While its roots are deep in the industrial automotive process, TPS itself is fundamentally an approach to agile and continuous improvement.12

Taiichi Ohno defined seven types of waste (Muda, a Japanese word meaning “wasteful”), and later an 8th category was added. Many modern implementations use the acronym DOWNTIME to categorize waste:3

Defect, or having to rework something, including poor designs or bugs.

Overproduction, producing more than is necessary (think about overengineering or building something the customer doesn’t value).

Waiting, any extra time when people, processes, or equipment is idle.

Non-utilized Talent, not fully applying the talents and skills of the team.

Transportation, unnecessary movement of the work product (think about moving a packaged binary through unecessary steps).

Inventory, excess work product that does not add value (have you ever maintained a server that is underutilized, or perhaps not used at all?).

Motion, movement that is unnecessary or that does not add value, including movement that is too quick or too slow.

Extra Processing, continuing to process beyond the requirements (think about optimizing processes that are not a bottleneck in the first place, or applying control processes that aren’t always necessary).

Running a quick waste walk

While it sounds involved, it’s actually pretty simple — although the subtleties can be tricky.

I think the best way to do a waste walk is during a live sprint. While you can do it retroactively, you’ll lose fidelity and it tends to be more challenging. On the other hand, if the team does the walk “on the fly” it should take less than 5 minutes a day for each team member.

If you use the referral button below, you’ll earn free premium access to Customer Obsessed Engineering. Just three referrals will earn a free month!

The first step is deciding how to bucket everyone’s time. This means identifying the team’s activities across the sprint, and creating simple, clear buckets where the team catalogues their time. It doesn’t need to be super detailed — actually, it should be pretty general to avoid ambiguity. Just enough detail to map to the team’s daily activities. Here’s an example:

Then, everyone classifies their time into each bucket every day, noting the time as “value add” or “non-value add.” The former means it was productive, while the latter means it was essentially unnecessary.

Coach the team on the difference between necessary and unnecessary work. Use the DOWNTIME categories as a baseline. For example, the first time we create a user story it adds value, whereas going back and reworking the story because of mistakes or incomplete understanding is non-value add.

In the example diagram above, a third of the team’s work effort was being lost to non-value add activity. This is shown in the lower right, by calculating the total non-value add time versus total value add time. What’s more, the team members put in an average of 88 hours each week, effectively trying to “catch up” on the lost time with overtime. The bottom line is simply this: If all the waste can be recaptured, fully one-third of the team’s budget and time would be freed up!

In the final analysis, we learned that the majority of lost effort went to requirements modification, rework, added quality assurance effort, and various meetings surrounding those activities.

That information is invaluable — it lets the team dig deeper, discover why so much rework is needed, and start capturing better requirements… and recapturing lost time.

Tips for a successful waste walk

Everyone takes part. Everyone that’s part of your organization is important. Don’t spend all of your time on the most urgent fires. Appreciate this is about preventing fires by investing everyone’s time.

Include stakeholders. You need to engage with every member outside of the normal ceremonies (like standups and planning). If they’re involved, they are part of the process.

Be observant. Establish trust so that your team brings your attention to the real issues at hand.

Be genuine. Be sure to recognizing people for doing the right thing, especially in support of continuous improvement activities.

Share. Keep repeating core concepts and praise others when you see it in practice.

Do no harm. Timing is everything. Plan in advance and don’t start your waste walk at crunch time or you risk making the team’s challenges more difficult.

Don’t bypass leadership. Make sure to involve leadership before implementing change to priorities, requirements, or design. This can be a huge win, too, simply be exposing gains from improvement.

Recognize this is step one. The waste walk gives you intelligence about where effort is being wasted. Use that intelligence to drive continuous improvemeent. Build a strategic plan to reduce the waste.

If you find Customer Obsessed Engineering and the Delivery Playbook valuable, please share it with your friends and coworkers.

Dan Sawyer, How To Do a Lean Waste Walk: Guide & Template, Expert Employee, expertemployee.com.

Nawras Skhmot, What is Lean?, Aug. 2017, The Lean Way blog, theleanway.net.

LEAN manufacturing: Tackling the 7 muda in materials handling, Apr. 2016, Rockwell Automation & OttoMotors.com.